Frequently Asked Questions

Find clear, straightforward answers to our most common questions here.

From technical support to product specifications, get the expert guidance

you need to save time and resolve queries efficiently.

Beam Smoke Detection

Find answers to common questions about beam smoke detection.

Fireray One

Find answers to common questions about the Fireray One beam smoke detector.

What is the detection range of the Fireray One?

Can this detector be installed by just one person?

Can the Fireray One be used in buildings that are prone to movement?

How does the Fireray One prevent false alarms?

How does the system handle interference from other beams?

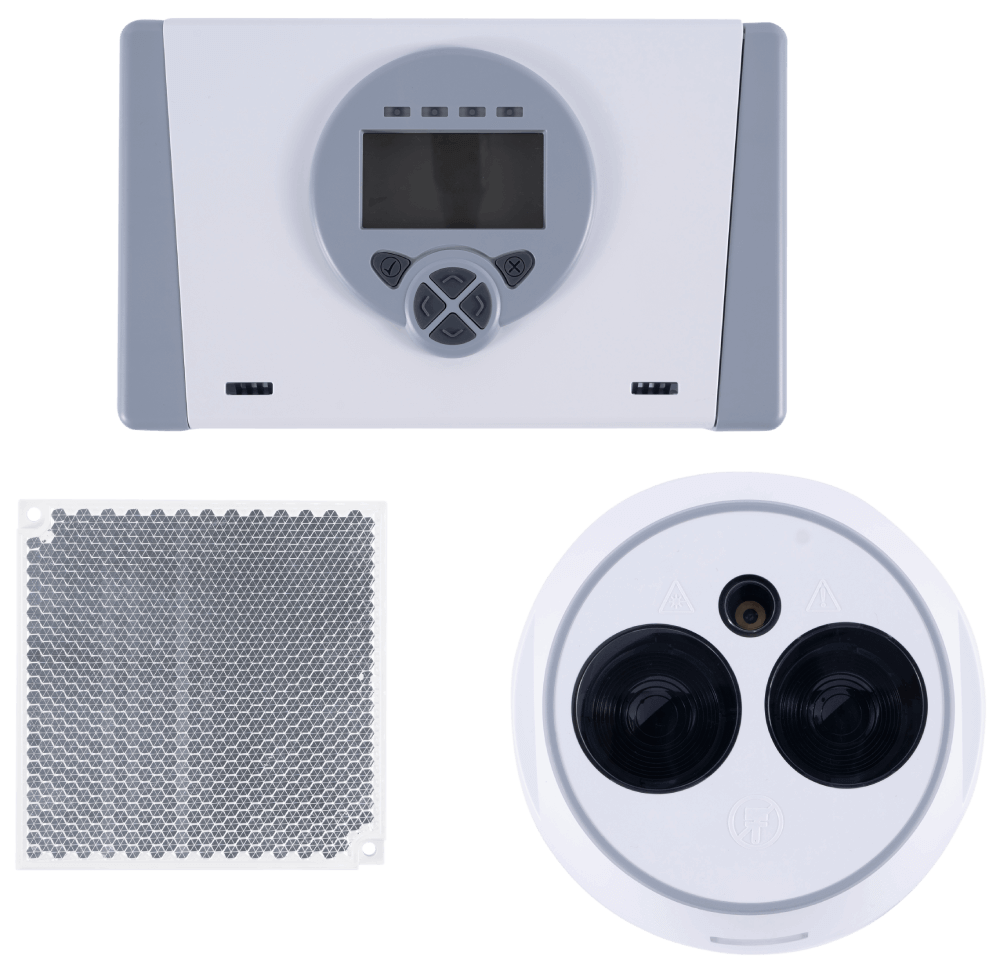

Fireray Hub Reflective

Find answers to common questions about the Fireray Hub Reflective beam smoke detector.

How does the motorised auto-alignment work?

What is Light Cancellation Technology™?

How many detector heads can one hub support?

What information does the event log provide?

What kind of environments is the Fireray Hub Reflective suitable for?

Fireray 5000

Find answers to common questions about the Fireray 5000 beam smoke detector.

What is the maximum range of the Fireray 5000?

How many detector heads can be connected to one controller?

How does the Fireray 5000 handle building movement?

Is the Fireray 5000 compliant with international standards?

Can the system be monitored and managed easily?

Fireray 3000

Find answers to common questions about the Fireray 3000 beam smoke detector.

What is the main advantage of an end-to-end beam detector?

How does the Fireray 3000 prevent false alarms from sunlight?

Can I manage the system without accessing the detectors on the ceiling?

How many detectors can be connected to one controller?

Is the Fireray 3000 suitable for both conventional and addressable fire alarm systems?

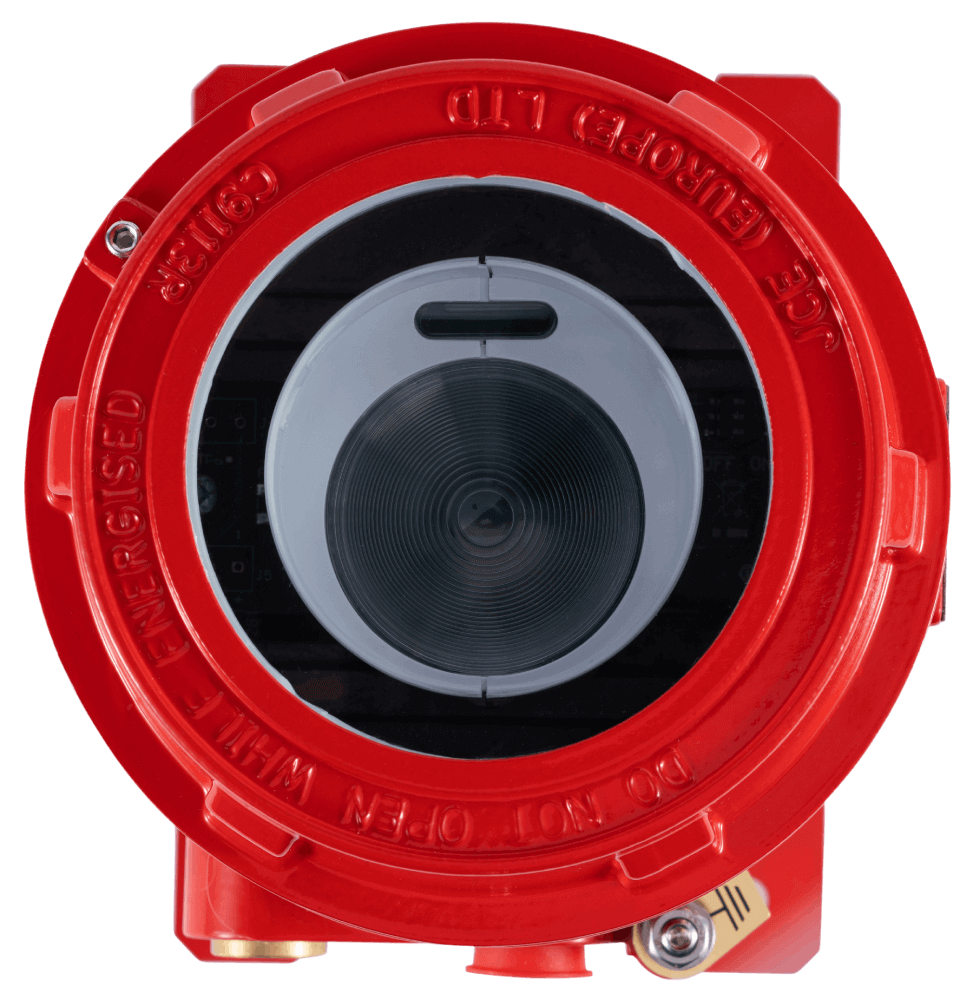

Fireray 3000 Ex d

Find answers to common questions about the Fireray 3000 Ex d beam smoke detector.

What does 'Ex d' certified mean?

In which specific environments can the Fireray 3000 Ex d be used?

How does the low level controller benefit the user?

What is Light Cancellation Technology?

Can multiple Fireray 3000 Ex d systems be installed close to each other?

Flame Detection

Find answers to common questions about flame detection.

Talentum 16000 IR2

Find answers to common questions about the Talentum 16000 IR2 flame detector.

How does the Talentum IR2 prevent false alarms?

The detector uses two IR sensors that analyse the wavelength and flicker frequency of radiation from a fire. For an alarm to be triggered, the signals must match the characteristics of a real flame, allowing the detector to ignore false sources like sunlight or welding arcs.

What is the main difference between an IR2 and an IR3 flame detector?

Can the Talentum IR2 detect fires with no visible flame?

What kind of environments is the Talentum IR2 suitable for?

Does the detector require regular maintenance?

Talentum 16000 IR3

Find answers to common questions about the Talentum 16000 IR3 flame detector.

What makes the Talentum 16000 IR3 flame detector different from other flame detectors?

The Talentum 16000 IR3 uses advanced Triple IR (IR3) sensing technology, which allows it to offer superior false alarm immunity compared to standard UV/IR or single IR detectors. This makes it ideal for complex industrial environments where reliability is critical.

Can the Talentum 16000 IR3 be used in hazardous environments?

How does the optical self-test feature work?

Is the Talentum 16000 IR3 suitable for outdoor use?

What is the typical detection range of the Talentum 16000 IR3?

Talentum 16000 UV IR2

Find answers to common questions about the Talentum 16000 UV IR2 flame detector.

What types of fire can the Talentum UV/IR2 detect?

The Talentum UV/IR2 is designed to detect a wide range of fires, including those from hydrocarbon fuels (such as n-heptane), invisible flames from hydrogen, and fires from methylated spirits. Its dual-sensor technology makes it a versatile flame detection solution.

How does the detector prevent false alarms?

What are the power requirements for this flame detector?

Is the Talentum UV/IR2 suitable for outdoor use?

What approvals does the Talentum UV/IR2 hold?

Talentum Test Torch

Find quick answers to your Talentum Test Torch queries.

Can the Talentum Test Torch be used on all Talentum flame detectors?

Yes, it is compatible with the full Talentum detector range.

How far can the testing be performed from?

Is the Calibration Kit included?

How does it simulate a flame?

What is its operational temperature range?

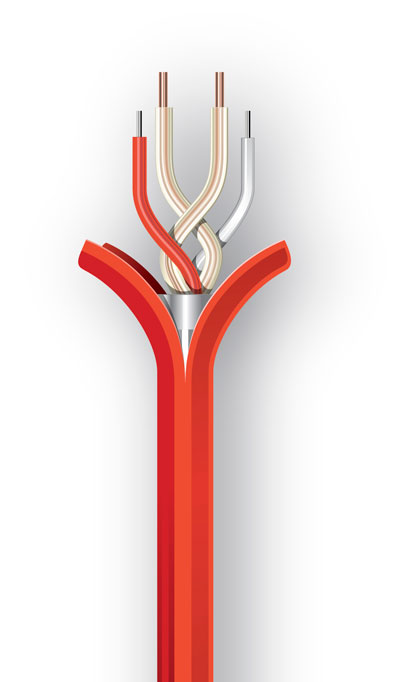

Linear Heat Detection

Find answers to common questions about linear heat detection.

Proreact Fixed Detectors

Explore common inquiries about our Proreact Fixed linear heat detector.

How does Proreact Fixed handle false alarms?

The system only activates at the preset temperature, minimizing false alarms typical in unreliable environments.

What are the installation requirements for Proreact Fixed?

Is Proreact Fixed compatible with my current alarm system?

What environments suit Proreact Fixed best?

What happens when the fixed temperature is reached?

Proreact Programmable Detectors

Find the answers to the most common questions about our Proreact Programmable linear heat detector.

What makes a programmable linear heat detector different?

Unlike fixed temperature detectors, a programmable linear heat detector allows you to set two distinct temperature thresholds: a 'pre-alarm' for early warning and an 'alarm' for activation. This provides greater flexibility and control in managing fire risks.

How does the system prevent false alarms from ambient temperature changes?

What is 'rate-of-rise' detection?

Can this heat detector be integrated with an addressable fire panel?

What are the ideal applications for this type of heat detector?

Technical Support/General

Find answers to common questions about FFE Technical Support.

Frequently asked questions and support

Who do I contact for technical support vs orders/aftercare?

What hours is technical support available?

What information do you need from me to troubleshoot quickly?

Where can I find manuals, datasheets, approvals, and wiring/commissioning guidance?

Do you offer training/webinars and how do I book it?

Is there a dedicated account manager for my company?

our customers choose FFE

FFE’s beam detectors were quick to install, easy to align, and performed flawlessly — even in a dusty warehouse environment. Their support team was responsive and incredibly knowledgeable. We’ll be specifying FFE on all future projects.

James Reynolds

Fire Systems Engineer, Axis Installations Ltd.

our customers choose FFE

FFE’s beam detectors were quick to install, easy to align, and performed flawlessly — even in a dusty warehouse environment. Their support team was responsive and incredibly knowledgeable. We’ll be specifying FFE on all future projects.

James Reynolds

Fire Systems Engineer, Axis Installations Ltd.

our customers choose FFE

FFE’s beam detectors were quick to install, easy to align, and performed flawlessly — even in a dusty warehouse environment. Their support team was responsive and incredibly knowledgeable. We’ll be specifying FFE on all future projects.

James Reynolds

Fire Systems Engineer, Axis Installations Ltd.

our customers choose FFE

FFE’s beam detectors were quick to install, easy to align, and performed flawlessly — even in a dusty warehouse environment. Their support team was responsive and incredibly knowledgeable. We’ll be specifying FFE on all future projects.

James Reynolds

Fire Systems Engineer, Axis Installations Ltd.

our customers choose FFE

FFE’s beam detectors were quick to install, easy to align, and performed flawlessly — even in a dusty warehouse environment. Their support team was responsive and incredibly knowledgeable. We’ll be specifying FFE on all future projects.

James Reynolds

Fire Systems Engineer, Axis Installations Ltd.